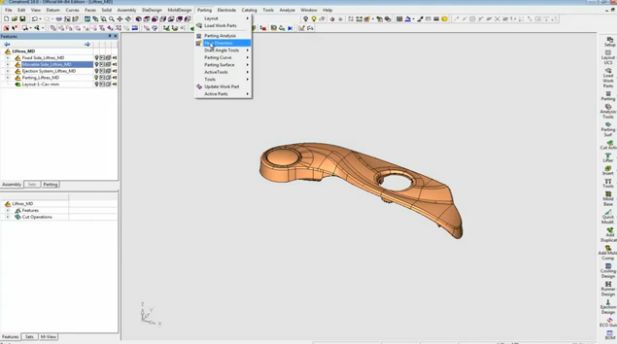

Cimatron Limited announced the official release of CimatronE 11, the newest version of its integrated CAD/CAM software solution.

"CimatronE 11 contains all that a tool shop needs to dramatically ramp up its productivity," said Mr Ira Bareket, Cimatron's VP Sales and Marketing.

"Existing CimatronE customers will benefit from the software's additional capabilities, new analysis tools, automations, and advanced processes and technologies.

"Those shops that do not yet use CimatronE will be amazed by the range of powerful mold- and die-specific tools and the way in which these can be employed to improve overall shop performance, enhance product quality, and minimize costs."

Key productivity improvements offered by the new version include:

- Fast and effective CAD for tooling

The new Wall Thickness Analysis tool ensures early detection of product integrity issues. The Assembly Mirror tool enables rapid mirroring of assemblies. New modeling features in solid and faces allow for faster work and greater flexibility. With enhanced drafting tools, drawings can be created quickly and there is easier manipulation of view and dimension positions.

- Seamless, optimized mold design

The new ECO Manager offers highly effective assessment and seamless incorporation of any number of engineering changes in an existing project. New tools enable the rapid creation of internal parting surfaces and lifter pockets, as well as the design and analysis of cooling channels.

- Flexible and intuitive die design

A new user-friendly die design environment enables flexible die creation and concurrent work by several designers. A new nesting tool ensures optimized material usage for transfer dies. The new Springback Analysis tool reduces the need for costly and time-consuming shop-floor iterations.

- Superior results with new machining strategies

Enhanced programming automation and new capabilities are now available in finish and rough, as well as ultra high volume material removal with VoluMill. In automated drilling there is improved collision and gouge prevention and more flexible and powerful sequences, and full control can be exercised over all gun drilling sequences.

- Quick and efficient NC programming

New capabilities ensure programming efficiency, template improvements offer greater automation, and NC on Assembly provides enhanced control over imported components. A new material removal simulator offers highly accurate results.

- Superior fast electrode design and manufacturing

Greater centralized control over visibility, as well as automatic coloring and finish automation, ensure the design and creation of electrodes in record time. |